In the age of automation and smart machinery, precision and adaptability are no longer optional — they’re essential. One technology quietly transforming industries is Intelligent Orientation Control. This advanced system enables machines to detect, interpret, and adjust their positioning in real time, enhancing performance, accuracy, and efficiency across a wide range of applications.

In this article, we’ll explore what this technology is, how it works, its benefits, real-world applications, and a compelling case study to illustrate its impact.

Content

Understanding Intelligent Orientation Control

Intelligent orientation control is a system that uses sensor-based orientation, smart motion control, and adaptive technology to help machinery maintain optimal positioning. Unlike conventional control systems that follow pre-set instructions, it continuously adapts to changing conditions by interpreting sensor data and making real-time adjustments.

Think of it as a self-correcting mechanism. Imagine a robotic arm assembling delicate electronics — even a slight misalignment can cause product defects. With this technology, the system automatically adjusts angles and positions, ensuring flawless assembly every time.

This makes it invaluable for industries where precision alignment technology is critical, such as robotics, aerospace, and advanced manufacturing.

How Intelligent Orientation Control Works

The functioning of IOC relies on a combination of smart sensors, data-driven algorithms, and real-time feedback loops. Here’s a simplified explanation:

- Sensing – Devices such as gyroscopes, accelerometers, and inertial measurement units (IMUs) collect orientation and positional data.

- Analysis – Control algorithms process the data to identify deviations or potential errors.

- Actuation – Commands are sent to actuators or motors to correct orientation.

- Continuous Learning – Advanced systems use machine learning to improve performance over time, anticipating adjustments before errors occur.

By integrating machine learning in automation, IOC can continuously refine itself, outperforming traditional control systems and maintaining stability even in unpredictable environments.

Core Components of Intelligent Orientation Control

Understanding the building blocks of IOC helps appreciate its effectiveness:

- Sensors: Capture real-time data on position, acceleration, and angular displacement.

- Control Algorithms: Adaptive algorithms, including PID controllers and AI-assisted decision models, determine corrective actions.

- Actuators: Execute precise movements based on algorithmic instructions.

- Feedback Loops: Ensure corrections are effective, continuously refining system performance.

These components work together to create a self-correcting ecosystem capable of automated positioning and precise orientation adjustments in dynamic settings.

Real-Life Case Study: Intelligent Orientation Control in Drones

A practical example of this technology can be found in the drone industry. A mid-sized drone manufacturer faced challenges with flight stability in windy conditions, causing frequent drift and inaccurate aerial data collection.

By implementing an intelligent orientation control system powered by sensor-based orientation and adaptive control algorithms, the company achieved remarkable results:

- Flight stability improved by 45%, even in gusty conditions.

- Battery efficiency increased due to reduced compensatory movements.

- Aerial mapping accuracy rose by 30%, ensuring reliable data capture for clients.

This case demonstrates how such a system enhances machine accuracy and operational efficiency in real-world applications.

Applications Across Industries

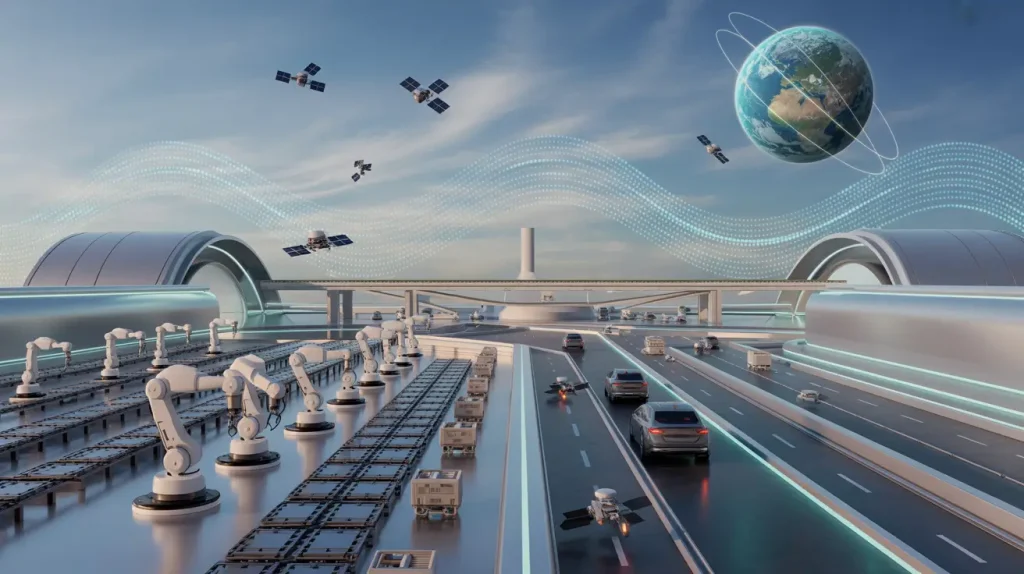

The potential of IOC extends far beyond drones:

- Robotics: Ensures precise motion control for assembly lines and robotic arms.

- Manufacturing: Maintains consistent alignment in high-speed production processes.

- Aerospace: Stabilizes satellites, spacecraft, and navigation systems.

- Automotive: Supports autonomous vehicle orientation and self-parking systems.

In all cases, intelligent orientation control enhances automation performance, reduces human intervention, and increases reliability.

Benefits of Orientation Control

Implementing IOC offers multiple advantages:

- Enhanced Accuracy: Corrects positional errors in real time.

- Operational Efficiency: Machines complete tasks faster and more reliably.

- Reduced Downtime: Minimizes errors that could cause production delays.

- Scalability: Adapts to different machines and industries.

However, there are challenges to consider:

- Higher initial integration costs.

- Requires skilled personnel for calibration and maintenance.

- Sensor errors or data noise can temporarily affect accuracy.

Despite these limitations, the benefits far outweigh the drawbacks, especially in industries where precision is paramount.

Future Trends in Orientation Control

The next evolution of IOC involves deeper integration with AI-driven predictive analytics. Future systems will not just react but anticipate orientation changes, enabling fully autonomous correction before errors occur.

Research suggests that future IOC solutions could leverage deep learning to reduce energy consumption, enhance adaptability, and create self-learning orientation systems suitable for highly complex automation tasks.

Conclusion

Intelligent Orientation Control is a game-changer for modern automation. By combining adaptive control technology, sensor-based orientation, and machine learning, it ensures machines operate with unmatched precision and efficiency. Just as Artificial Intelligence Tickets streamline complex support processes through smart automation, this technology sets new benchmarks for operational intelligence. From drones to robotic arms and aerospace applications, this system is defining the standard for smart, reliable, and autonomous operations. For engineers, manufacturers, and innovators, mastering it is not just an advantage — it’s becoming a necessity in a competitive, technology-driven world.

FAQ’s:

What is intelligent orientation control?

It’s a system that uses sensors, algorithms, and actuators to automatically maintain optimal machine orientation in real time.

Why is it important for robotics and automation?

It improves precision, reduces errors, and enhances operational efficiency.

Can IOC replace manual control entirely?

In many automated systems, yes, but human oversight is often recommended for complex scenarios.

What are the limitations of IOC?

Initial costs, sensor calibration requirements, and potential minor errors from data noise.

David French is an avid tech enthusiast. He loves to read about new innovations and technologies as well as share his thoughts on what he finds. He has a degree in English from the University of South Florida, but spends most of his time writing about technology rather than reading literature.